Supply chain manufacturing is a tightly integrated network of companies involved in manufacturing and delivering a product. It’s focused on efficiency and effective resource utilization from end to end.

However, it’s not easy to develop these tightly integrated networks, ensure all processes are optimized, and ensure the efficient flow of materials and goods. In this article, We’ll dive into the differences between supply chains and manufacturing processes as well as the best ways to align the two below.

What Is Supply Chain Manufacturing?

Image by Jonathan from Pixabay

Disruptions in supply chains have outsized impacts on manufacturing companies. Organizations face issues with:

- Shortages of components and supplies

- Transportation delays

- Rising material costs

Supply chain manufacturing aims to reduce or eliminate these challenges with tightly integrated manufacturing and supply chain strategies that prioritize high resource utilization and efficient material flows from procurement to production.

Why Do You Need Supply Chain Manufacturing?

When issues arise in the supply chain, production rates and profits suffer, which is especially problematic in periods of economic uncertainty. The risks of ongoing contracts going unfulfilled and inefficiencies eating into profitability over time warrant more attention being paid to the linkages between supply chains and the manufacturing processes they connect.

For executives in the space, it can be tough to reconcile cost-minimization goals with the need for redundancy and compliant production processes. Supply chain engineering and optimization measures taken for each of these concerns must take the entire supply chain and manufacturing strategy into account in order to be effective.

Supply chain manufacturing brings these various needs and goals together by creating a cohesive, integrated network of the companies involved in the supply chain to gain better control over efficiency and optimization.

Supply Chains vs. Manufacturing

Although the two are inextricably linked, there are distinct differences between supply chains and manufacturing processes. Here are a few key points regarding each that help to highlight their roles in the unified process of producing physical goods.

Supply chains:

The supply chain encompasses everything from sourcing raw goods to distributing finished products. Every transaction that takes place along the journey from materials to sales makes up the supply chain’s intricate network. As manufacturing techniques improve, so too does the supply chain’s overall efficiency.

Supply chains involve more than mere transactions. All of the people involved in the process of producing physical goods are considered a part of the chain as well. So too is the information needed to keep the chain connected and the technology used to transform materials into components.

Supply chains can take on a variety of forms, such as a continuous flow model in which similar products are rapidly created without significant breaks in material sourcing or manufacturing.

Manufacturing:

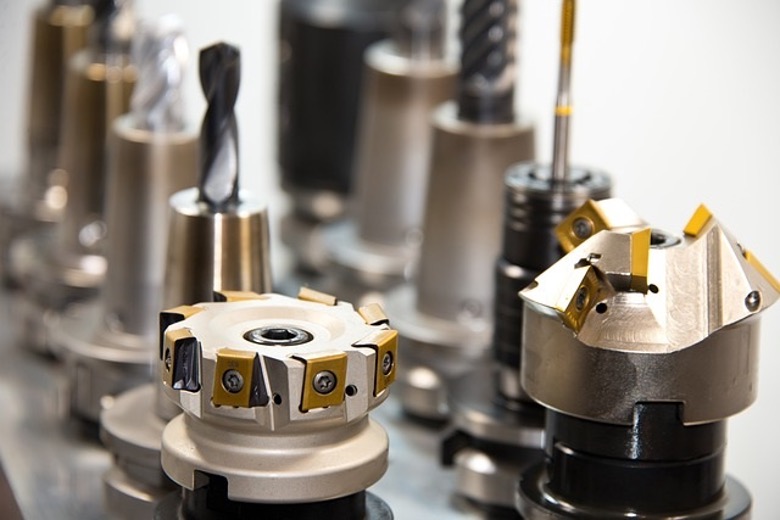

Image by Michael Schwarzenberger from Pixabay

Manufacturing is all about transformation. Raw materials are converted into finished products that can be sold to other organizations or end users.

Manufacturing is one of the most important components of a supply chain and can have a major impact on its efficiency. Bottlenecks in an organization’s manufacturing steps often ripple through the rest of its supply chain, creating delays in other areas.

Managing the procurement portions of your supply chain can make it easier to handle critical facets of manufacturing, such as quality control.

Examples of Supply Chain Manufacturing

Supply chain manufacturing has become a popular supply chain strategy for creating products of all kinds at scale. Here are a few examples of this approach to manufacturing that have proven to be successful in their own industries:

Toyota Production System

This system leverages an impressively coordinated just-in-time procurement and creation strategy that perfectly aligns Toyota’s supply chain with its manufacturing processes. This system dramatically reduces the amount of time it takes Toyota to produce and deliver vehicles, including fully customized orders. In this case, special attention is also given to concepts such as “Jidoka” and “Kaizen.” The former focuses on safety during the manufacturing process and the other revolves around incremental improvements in reliability.

Mars Inc. Leveraging Local Production and AI

Confectionary company Mars Inc. has devoted considerable resources toward maximizing local production of their best-selling products in the US. They’ve accomplished this with the help of artificial intelligence that simultaneously monitors logistics, quality assurance practices, and more along their entire supply chain. Mars has even taken to managing its own network of cocoa producers to ensure only reputable sourcing is allowed.

Learn more about how companies are overhauling supply chains to ease bottlenecks in this video from The Wall Street Journal:

Supply Chain Manufacturing Best Practices

The following best practices can help to simplify your supply chain manufacturing efforts:

Choose Modular Designs

Considering the impact your product’s design has on later production processes can help to alleviate potential supply chain manufacturing issues, and embracing the philosophy of modular product design allows for individual components to be built and sourced in a variety of ways. This makes redundancy and resilience across your entire supply chain easier to achieve. However, you’ll need to pay special attention to the ways in which individual components connect to each other in order to avoid assembly complications down the line.

Leverage Standard Components

Opting for standardized components as opposed to all-custom inclusions can dramatically reduce the cost of bringing your product designs to life. Whether you choose readily available screws and brackets as building blocks for your products or incorporate electronic parts into your design that can be sourced from a large variety of vendors, building around these types of components can be a great way to enhance your supply chain manufacturing strategy.

Maximizing the potential of your supply chain manufacturing systems requires in-depth industry expertise and careful analysis. Argano’s digital technology and supply chain experts deliver these and much more, helping to guide your organization’s efforts with unbiased suggestions for practical solutions. Contact us today to learn more about how Argano’s experts can help you develop a robust digital foundation to optimize resilience, agility, and visibility in supply chain management.